WEBGRATE is generally supplied in either of three standard finishes:

The minimum average coating required by these standards is 610gms/m2

WEBGRATE is generally supplied in either of three standard finishes:

The minimum average coating required by these standards is 610gms/m2

No 20, Jalan IM 14/1, Kawasan Perindustrian 14, Bandar Indera Mahkota, 25200 Kuantan, Pahang D. Makmur.

T: (+6)09 573 3499

F: (+6)09 573 2468

E:sales@multisteel.net

Pipes

Tubes

Fittings

Plates

Bars & Rods

Flanges & Fittings

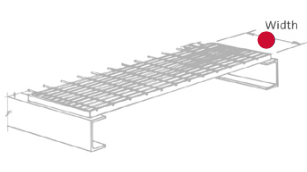

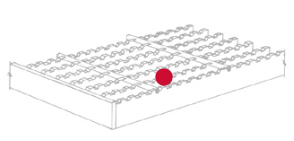

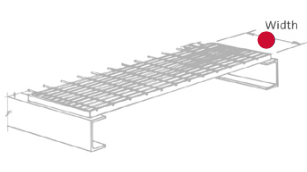

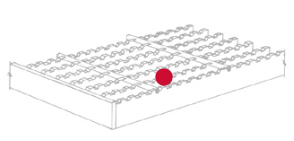

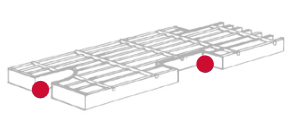

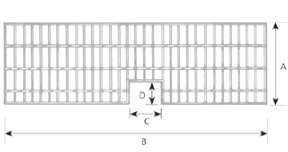

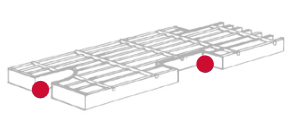

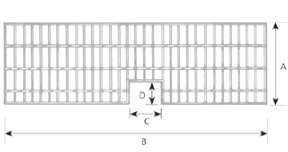

Webgrate

Job Vacancy

Corporate Benefits

Application Form

Home

Company

Products

Careers

Contact

Terms of Uses

Privacy Policy

PDPA – Privacy Policy

No 20, Jalan IM 14/1, Kawasan Perindustrian 14, Bandar Indera Mahkota, 25200 Kuantan, Pahang D. Makmur.

T: (+6)09 573 3499

F: (+6)09 573 2468

E:sales@multisteel.net

Pipes

Tubes

Fittings

Plates

Bars & Rods

Flanges & Fittings

Webgrate

Job Vacancy

Corporate Benefits

Application Form

Home

Company

Products

Careers

Contact

Terms of Uses

Privacy Policy

PDPA – Privacy Policy